CATEGORIES

FEATURED PRODUCTS

High Quality ERW Steel Pipe,ERW Seamless Carbon Steel Pipe for Waterworks

High Quality ERW Steel Pipe,ERW Seamless Carbon Steel Pipe for Waterworks

Tianjin Xingrong Metal Products Co., LTD

Tianjin Youfa steel pipe group were founded on July 1st, 2000, with the headquarters location at the largest welded pipe production base in China-Daqiuzhuang Village, Tianjin city, which is a large-scale steel pipe manufacturing enterprise producing many kinds of pipe products GALVANIZED STEEL PIPE, ERW STEE LPIPE, SQUARE AND RECTANGULAR STEEL TUBE, GALVANIZED SQUARE PIPE, SPIRAL STEEL TUBES, STAINLESS STEEL PIPE, SCAFFOLDING, AND PIPE FITTINGS. have been rated as top 500 enterprises of China in the same industry,and as top 500 manufacturing of china.

Youfa brand was affirmed as a China renowned brand by SAIC trademark bureau in March 2008.

| Product | Hot Dip Galvanized Steel Pipe | |

| Material | 16Mn,Q345B,T1,T2,T5,T9,T11,T12,T22,T91,T92,P1,P2,P5,P9,P11,P12,P22,P91,P92,15CrMO,Cr5Mo,10CrMo910,12CrMo,13CrMo44,30CrMo,A333 GR.1,GR.3,GR.6,GR.7 |

|

| Gr.B,X42,X46,X52,X60,X65,X70,X80, | ||

| ASTM A53A/A53B/ A178C/A106B API5L | ||

| ST37,ST37-2,DIN 1629 ST35, ST45,DIN 17175 ST35.8,DIN 17175 19Mn5 | ||

| Grade | Q195 = S195 / A53 Grade A | |

| Q235 = S235 / A53 Grade B / A500 Grade A / STK400 / SS400 / ST42.2 | ||

| Q345 = S355JR / A500 Grade B Grade C | ||

| Q235, Q345, S235JR, S275JR, STK400, STK500, S355JR, GR.B-D | ||

| Standard | EN39, BS1139, BS1387, EN10255,ASTM A53, ASTM A500, A36, ASTM A795,ISO65, ANSI C80, DIN2440, JIS G3444, | |

| Inspection | ISO,BV,SGS,MTC | |

| MOQ | 100/ton-1000ton According to customer requirements | |

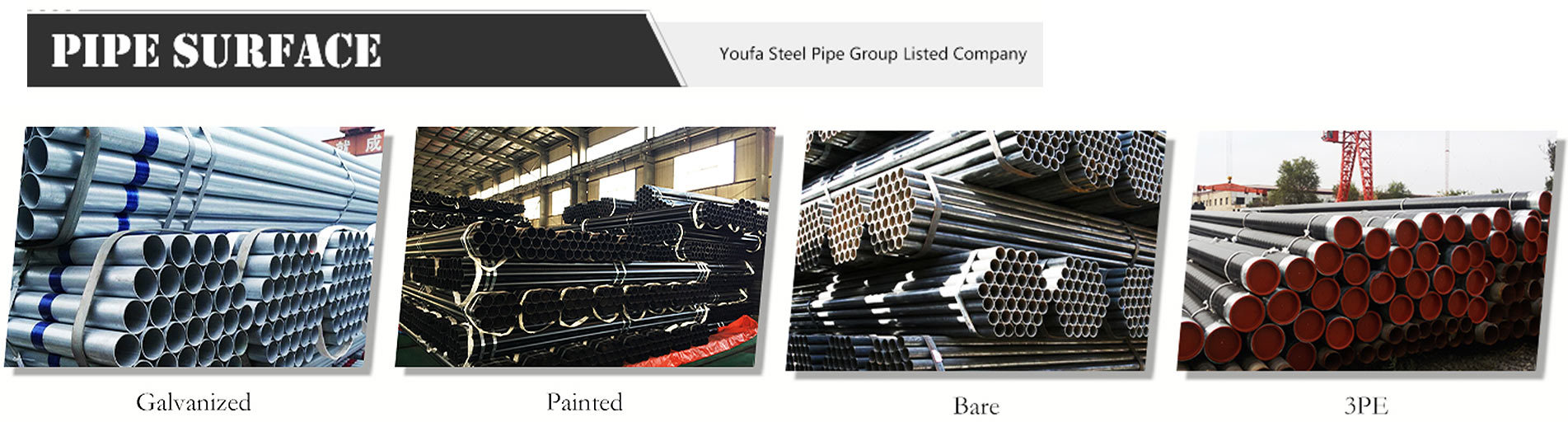

| Surface | Zinc coating 200-500g/m2 (30-70um) | |

| Ends | Plain ends | |

| with or without caps | ||

| payment method | L/C D/P D/A TT |

Galvanized Carbon Steel Pipe Size Chart :

|

DN |

OD |

ASTM A53 / API 5L / ASTM A795 |

BS1387 / EN10255 |

|||||

|

SCH10S |

STD SCH40 |

SCH80 |

Light |

Medium |

Heavy |

|||

|

MM |

INCH |

MM |

MM |

MM |

MM |

MM |

MM |

|

|

15 |

21.3 |

1/2" |

2.11 |

2.77 |

3.73 |

2 |

2.6 |

- |

|

20 |

26.7 |

3/4“ |

2.11 |

2.87 |

3.91 |

2.3 |

2.6 |

3.2 |

|

25 |

33.4 |

1" |

2.77 |

3.38 |

4.55 |

2.6 |

3.2 |

4 |

|

32 |

42.2 |

1-1/4" |

2.77 |

3.56 |

4.85 |

2.6 |

3.2 |

4 |

|

40 |

48.3 |

1-1/2" |

2.77 |

3.68 |

5.08 |

2.9 |

3.2 |

4 |

|

50 |

60.3 |

2" |

2.77 |

3.91 |

5.54 |

2.9 |

3.6 |

4.5 |

|

65 |

73 or 76 |

2-1/2" |

3.05 |

5.16 |

7.01 |

3.2 |

3.6 |

4.5 |

|

80 |

88.9 |

3" |

3.05 |

5.49 |

7.62 |

3.2 |

4 |

5 |

|

90 |

101.6 |

3-1/2" |

3.05 |

5.74 |

8.08 |

|||

|

100 |

114.3 |

4" |

3.05 |

6.02 |

8.56 |

3.6 |

4.5 |

5.4 |

|

125 |

141.3 |

5" |

3.4 |

6.55 |

9.53 |

5 |

5.4 |

|

|

150 |

168.3 |

6" |

3.4 |

7.11 |

10.97 |

5 |

5.4 |

|

|

200 |

219.1 |

8" |

3.76 |

8.18 |

12.7 |

|||

|

250 |

273.1 |

10" |

4.19 |

9.27 |

15.09 |

|||

Application:

Construction / building materials steel pipe

Scaffolding steel pipe

Fence post steel pipe

Fire protection steel pipe

Greenhouse steel pipe

Low pressure liquid, water, gas, oil, line pipe

Irrigation pipe

Handrail pipe

PIPE ENDS TREATMENT:

*THREADED BOTH ENDS (BS or ASTM standard)One end with plastic caps, and the other end with coupling;

*GROOVED ENDS (BS or ASTM standard);

*PLAIN ENDS (regular situation);

*Add plastic caps or not;

*BEVEL ENDS WITH PLASTIC CAPS( 30 degree bevel suitable to welding ).

Strict Quality Control:

1) During and after production, 4 QC staffs with more than 5 years experience inspect products in random.

2) National accredited laboratory with CNAS certificates

3) Acceptable inspection from third party appointed/paid by buyer, such as SGS, BV.

4) Approved by Malaysia, Indonesia, Singapore, Philippines, Australia, Peru and UK. We own UL /FM, ISO9001/18001, FPC certificates.

PACKING AND DELIVERY: -- Round hollow section pipe

1. OD 219mm and below In hexagonal seaworthy bundles packed by steel strips, With two nylon slings for each bundles

2. above OD 219mm in bulk or according to custom opinion

3. 25 tons/container and 5 tons/size for a trial order;

4. For 20" container the max length is 5.8m;

5. For 40" container the max length is 11.8m.

About us:

Tianjin Youfa Steel Pipe Group Co., Ltd was founded on July 1st, 2000. There are totally about 8000 employees, 13 factories, 293 steel pipe production lines, 3 national accredited laboratory, and 1 Tianjin government accredited business technology center.

5 factories producing galvanized steel pipe under Youfa Group until 2021;

60 hot dipped galvanized steel pipe production lines;

4,240,000 tons annual output of gi pipe;

104,300 tons exported around the world.

Galvanized Steel Pipe Weight Coefficient

Nominal Wall Thickness (mm): 2.0, 2.5, 2.8, 3.2, 3.5, 3.8, 4.0, 4.5.

Coefficient Parameter (c): 1.064, 1.051, 1.045, 1.040, 1.036, 1.034, 1.032, 1.028.

Note: The mechanical properties of steel are important indicators to ensure the final performance (mechanical properties) of steel, which depend on the chemical composition and heat treatment system of the steel. In the steel pipe standards, according to different usage requirements, tensile properties (tensile strength, yield strength or yield point, elongation), hardness, toughness indicators, and high and low temperature performance required by users are specified.

Steel Grade: Q215A; Q215B; Q235A; Q235B

| Product | Hot Dip Galvanized Steel Pipe |

| Material | Carbon Steel |

| Grade | Q195 = S195 / A53 Grade A Q235 = S235 / A53 Grade B / A500 Grade A / STK400 / SS400 / ST42.2 Q345 = S355JR / A500 Grade B Grade C |

| Standard | EN39, BS1139, BS1387, EN10255,ASTM A53, ASTM A500, A36, ASTM A795,ISO65, ANSI C80, DIN2440, JIS G3444,

GB/T3091, GB/T13793 |

| Surface | Zinc coating 200-500g/m2 (30-70um) |

| Ends | Plain ends |

| with or without caps |

Galvanized Carbon Steel Pipe Size Chart :

|

DN |

OD |

ASTM A53 / API 5L / ASTM A795 |

BS1387 / EN10255 |

|||||

|

SCH10S |

STD SCH40 |

SCH80 |

Light |

Medium |

Heavy |

|||

|

MM |

INCH |

MM |

MM |

MM |

MM |

MM |

MM |

|

|

15 |

21.3 |

1/2" |

2.11 |

2.77 |

3.73 |

2 |

2.6 |

- |

|

20 |

26.7 |

3/4“ |

2.11 |

2.87 |

3.91 |

2.3 |

2.6 |

3.2 |

|

25 |

33.4 |

1" |

2.77 |

3.38 |

4.55 |

2.6 |

3.2 |

4 |

|

32 |

42.2 |

1-1/4" |

2.77 |

3.56 |

4.85 |

2.6 |

3.2 |

4 |

|

40 |

48.3 |

1-1/2" |

2.77 |

3.68 |

5.08 |

2.9 |

3.2 |

4 |

|

50 |

60.3 |

2" |

2.77 |

3.91 |

5.54 |

2.9 |

3.6 |

4.5 |

|

65 |

73 or 76 |

2-1/2" |

3.05 |

5.16 |

7.01 |

3.2 |

3.6 |

4.5 |

|

80 |

88.9 |

3" |

3.05 |

5.49 |

7.62 |

3.2 |

4 |

5 |

|

90 |

101.6 |

3-1/2" |

3.05 |

5.74 |

8.08 |

|||

|

100 |

114.3 |

4" |

3.05 |

6.02 |

8.56 |

3.6 |

4.5 |

5.4 |

|

125 |

141.3 |

5" |

3.4 |

6.55 |

9.53 |

5 |

5.4 |

|

|

150 |

168.3 |

6" |

3.4 |

7.11 |

10.97 |

5 |

5.4 |

|

|

200 |

219.1 |

8" |

3.76 |

8.18 |

12.7 |

|||

|

250 |

273.1 |

10" |

4.19 |

9.27 |

15.09 |

|||

Test Pressure Value/Mpa: 3Mpa for D10.2-168.3mm; 5Mpa for D177.8-323.9mm

Current National Standard for Galvanized Steel Pipes

Galvanized Pipe National Standards and Size Standards

GB/T3091-2015 Welded Steel Pipes for Low-Pressure Fluid Delivery

GB/T13793-2016 Straight Seam Electric Welded Steel Pipes

GB/T21835-2008 Welded Steel Pipe Dimensions and Unit Length Weight

Usage of Galvanized Steel Pipes

Instructions for Use of Galvanized Steel Pipes

The commonly referred galvanized pipes, the type of iron pipes used for gas and heating, are also galvanized pipes. As water pipes, after using for several years, a large amount of rust scale is produced inside the galvanized pipes. The yellow water flowing out not only pollutes the sanitary ware but also contains bacteria that breed on the rough inner walls. The rust corrosion causes the content of heavy metals in the water to be too high, which severely endangers human health

.

Related Products